Jag rev counter is electronic. But I also bought a conversion kit for it from a company called Spyder. So I have old school looks with modern electronics. Hopefully :-)

DRL152K Marina based roadster rebuild

Collapse

X

-

-

A litle bit of progress, probably the last for a while as my wife has just this week had a hip replacement and apparently being nurse and chief cook and bottlewasher is now more important lol.

I made a backing plate for the dashboard to take the three instruments I am using. The centre place is a giant rev counter from a Jag. Left and right of it will be a fuel gauge and combined oil pressire / water temperature gauge. The plan is to make the actual dash from aluminium recycled from the old bonnet sides which I will be remaking.

dashboard1 by Robin Martin, on Flickr

dashboard1 by Robin Martin, on Flickr

In the lower part of the picture you can see the start of my new gearbox support. Originally the gearbox was suspended from the transmission tunnel - an arrangement I didn't particulary like.

That's all for now...

Comment

-

It's even worse when you realise the inner seat belt mounting point was the thin aluminium tunnel reinforced only by some fabricated steel corners!Originally posted by martinclan56 View PostOriginally the gearbox was suspended from the transmission tunnel - an arrangement I didn't particulary like.

That's all for now...

Comment

-

-

I managed to find a few odd half hours in between being Florence Nightingale and Jamie Oliver :-)

I have completed the new gearbox mount which will also support the transmission tunnel and hence floor. It also means I can make the transmission tunnel sides in two parts that will fit in my bender.

gearbox_mount by Robin Martin, on Flickr

gearbox_mount by Robin Martin, on Flickr

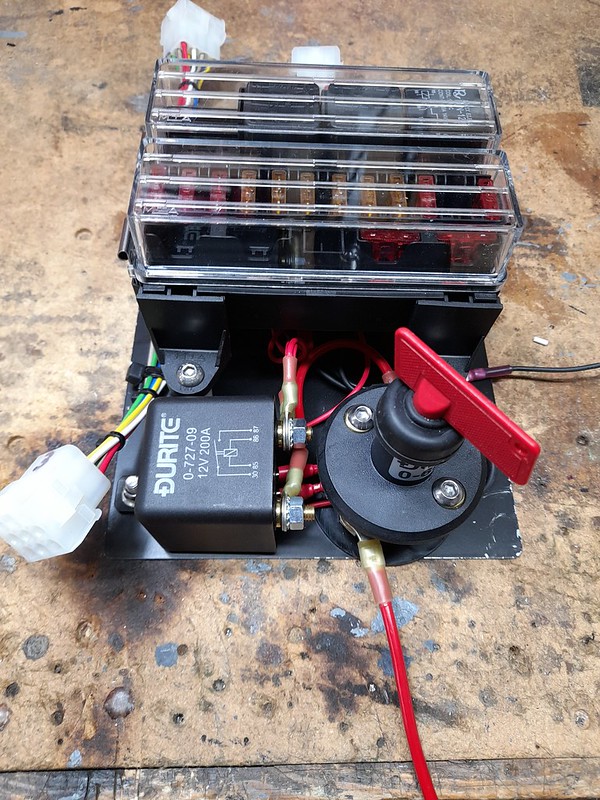

And I also made up and mounted the fuse/relay box which will also act as a distribution point for the electrics hopefully avoiding the spaghetti look. I used a similar arrangement in the Pembleton.

fuse_box1 by Robin Martin, on Flickr

fuse_box1 by Robin Martin, on Flickr

And on the engine side two mate'n'lock connectors to avoid cables having to go through the bulkhead.

fuse_box2 by Robin Martin, on Flickr

fuse_box2 by Robin Martin, on Flickr

The battery box may or may not be fitted below the fusebox. Undecided atm.

Comment

-

I have completed the transmission tunnel. Pleased with the result but folding the long lengths of sheet steel almost destroyed my home made bender. Steel is so much tougher than ally. Hopefully I wont need to do it again.

Getting a good fit at the bulkhead end proved tricky as the tunnel is not square to the bulkhead and the chassis that supports the torsion bars is also at a slight angle. But got there is the end after a lot of bad words....

The observant may notice that I used a stretcher / shrinker to acheive the flare in the tunnel at the diff end, and again at the gearbox end. You can still see the grip marks on the flange.

transmission tunnel 2 by Robin Martin, on Flickr

transmission tunnel 2 by Robin Martin, on Flickr

transmission tunnel 3 by Robin Martin, on Flickr

transmission tunnel 3 by Robin Martin, on Flickr

Next job - handbrake. I have purchased one of Richard Oakes trigger handbrakes and a lovely piece of kit it is too...

Comment

-

Suggest you might want to attach the top of the transmission tunnel with Rivnuts as I have had to get under it on a number of occasions and it makes access easier.Originally posted by martinclan56 View PostI have completed the transmission tunnel. Pleased with the result but folding the long lengths of sheet steel almost destroyed my home made bender. Steel is so much tougher than ally. Hopefully I wont need to do it again.

Getting a good fit at the bulkhead end proved tricky as the tunnel is not square to the bulkhead and the chassis that supports the torsion bars is also at a slight angle. But got there is the end after a lot of bad words....

The observant may notice that I used a stretcher / shrinker to acheive the flare in the tunnel at the diff end, and again at the gearbox end. You can still see the grip marks on the flange.

transmission tunnel 2 by Robin Martin, on Flickr

transmission tunnel 2 by Robin Martin, on Flickr

transmission tunnel 3 by Robin Martin, on Flickr

transmission tunnel 3 by Robin Martin, on Flickr

Next job - handbrake. I have purchased one of Richard Oakes trigger handbrakes and a lovely piece of kit it is too...

Adrian

Comment

-

-

Thanks for the comments guys.

I haven't decided on how to fix the top panel yet. I have made it in three pieces so my thinking was to pop rivet some of it and use rivnuts on the bit it would be handy to remove for access.

Cheers, Robin

Comment

-

I have a handbrake! And it works :-)

handbrake 1 by Robin Martin, on Flickr

handbrake 1 by Robin Martin, on Flickr

I have to say that the trigger handbrakes are beautifully made and, as a bonus, you get to deal directly with the famous Richard Oakes.

The handbrake cable from the Marina is the first I have ever seen with a built in grease nipple. You can just about see it on the centre right of the picture.

handbrake2 by Robin Martin, on Flickr

handbrake2 by Robin Martin, on Flickr

Comment

-

I have taken the opportunity of the last few mild days to complete the fusebox and battery box. The 3 connectors you can see are for the dashboard and rear loom. 2 other connectors appear the other side of the bulkhead, 1 for the engine and the other for the front lights etc. I have used industrial mate'n'lock connectors mainly as I had a load left over from the Pembleton build.

The ignition switch I have chosen is a fancy, key operated, industrial job but only has a low switching capability hence the large relay.

And of course the inevitable isolation switch.

For safety, as the battery in in the footwell rather than being under the bonnet, I have fitted two large fuses to the battery box, 1 for the starter (125 Amps) and the other for everything else (40 Amps).

Just need the actual battery now!

fusebox by Robin Martin, on Flickr

fusebox by Robin Martin, on Flickr

fusebox_mounted by Robin Martin, on Flickr

fusebox_mounted by Robin Martin, on Flickr

Next step will be the dashboard....

Comment

-

Very neat, Robin, but your passenger is going to keep kicking that and changing fuses will be a real pain crawling into the footwell!

Comment

-

Yes - I may put a cover over the whole thing.Originally posted by jon_wilkinson View PostVery neat, Robin, but your passenger is going to keep kicking that and changing fuses will be a real pain crawling into the footwell!

But fuses blowing - Never. I'm an electrical engineer and they wouldn't dare ;-)Last edited by martinclan56; 02-02-24, 01:25 PM.

Comment

Comment