I had a page like this is going to be, all typed, with photos which had taken probably an hour to prepare.........and then lost it! I know what Steve Green was complaining about now! The lack of a "save off line ", or "auto save" which it says it does, (but does not!) would have saved me from having to do this page all over again!

It is fascinating what you can learn from the web, and just how much information is available. And if you are smart you try to find someone who has done all the work before hand! I am a great believer in not re-inventing the wheel again. I can then concentrate on things which are new or individual to what I want to achieve.

BMW fit the same gearbox on the back of 4 cylinder engines as well as 6 cylinder ones, and also fit them in different models. So to get the gear stick in the right position for each model requires them to fit different length linkages.

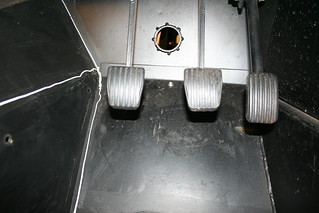

The upper linkage connects to the back of the gearbox through the rubber mount on the left, and is supported at the rear via another rubber mount around the spiked end, which I clamped to the underside of the transmission tunnel. The gear stick pivots in a ball and cup arrangement in the circular casting.

BMW measure the distance between the centres of the gearbox mount, and the gear stick ball and cup, and then stamp it on the casting. If you blow this photo up it is possible to read "C=257.2" - very precise the Germans!

Like a lot of kit car builders I sat in my drivers seat, made some "brrmm - brrmm" noises and considered where I would like my gear stick to be positioned in my Cabrio. After a while I concluded I'd like it 25mm further back than the link I had received with my engine/gearbox from the 325i saloon. This would "fall to hand" more easily, and provide clearance to the centre console I had in mind (much more of that later).

A trip to Stoneleigh confirmed my thinking when I saw Chris Cunliffe had added a crank to the top of his gear stick to bring it further back into to his cabin.

Research then revealed that BMW made a range of these linkages, and there was one marked "C=277" which was fitted to their Compact: this would be pretty close to ideal - I could angle the gear stick back a little by shortening the lower link (as seen above) if I felt it necessary.

Patrick Short had been building a BMW Sportster and had done a lot of research into BMW gearsticks, and had aquired quite a collection - see below!. They vary the length of the gear stick above the ball and cup, and the length below it; this obviously affects the amount of gear knob movement required to move between gears. I had to choose one which had a short lower length, to avoid the lower gear linkage fouling on the prop shaft.

There are two gear sticks with short lower lengths in Patrick's selection - the Z3 1.9, and the Z4 2.5.

The figure Patrick has typed on the centre of each stick is the ratio of upper stick length over lower length. The lower this figure, the quicker the shift is, but there is a drawback to this - the lower the ratio the harder the mechanical effort to change gear.

So I made up some gash gear sticks and played around and determined the gear stick from Z3 1.9 would be optimum for me.

Before showing the next photo, I should also explain that there are always competing restraints on car design. The 3 dimensional position of the gear knob is obviously determined by where you want it to drop your hand to it easily, but there are other factors to consider- in my case the hand brake position, both fore/aft, and in height.

This is with the Z3 1.9 gearstick, and a gash gear knob (a standard one with 25mm cut off the bottom to lower it to where I felt it was right). From this photo, you can see I was limited to how far back in to the cabin I could bring the gear stick by the hand brake.

The rubber boot came from the BMW's gaitor: it is much neater than the square Sierra gaitor, and fits nicely inside one of the chromed rings that are widely available.

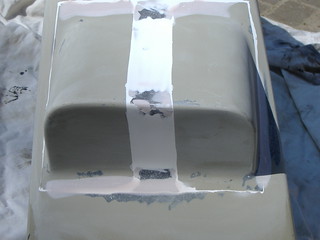

What is not obvious, is that I had reduced the height of the transmission tunnel at the back (to get access to my seat adjusters), making it slope down to the back. So, when I mounted the standard Sierra handbrake it was angled much more upwards toward the wind screen. I therefore cut the front leg off, and reduced its depth by 15mm, and at the same time welded a thicker foot to the rear fixing which, when combined, lowered the handle by around 50mm, and brought it parallel with my tunnel top.This positioned the handbrake handle as low as I could comfortably get my fingers around it without catching my knuckles on the tunnel top. It also placed it below the gearknob height - important when considering a hill start and gear change.

Whilst at it, I welded a second foot to both the front and rear single legs, so that my hand brake is now much more rigidly mounted side to side. (Floppy hand brakes do not inspire me with confidence!)

Whilst doing all this, it also seemed sensible to fit a new cup, and rubber mount: and it did tighten up the feel of the gear change.

Although a long way out of chronological order, the finished gearstick currently looks like this:

I bought a piece of olive root in Corfu, originally crafted as a candle holder, as it had such beautiful graining: I then turned it down in to a gear knob shape. With a bit of judicious filing of the BMW gate badge and the top of the knob, it has fitted nicely.

. You mention the open boss on the top for the through bolt, the 7 1/2" having a solid boss also has two shorter bolts in tapped holes in this boss, so a further identifier. Peter.

. You mention the open boss on the top for the through bolt, the 7 1/2" having a solid boss also has two shorter bolts in tapped holes in this boss, so a further identifier. Peter.

Leave a comment: