Keep it coming, I'm really enjoying this thread.

Adrian

Adrian

If this is your first visit, be sure to look in the introductory information by clicking on this link: FAQ . You may have to join as a member before you can post. To start viewing messages, select the forum that you want to visit from the selection below.

If you have questions please use the Contact Page for a personal response

If you wish to contribute to our discussions then please consider joining the club - it costs only £24 per year and is worth every penny!

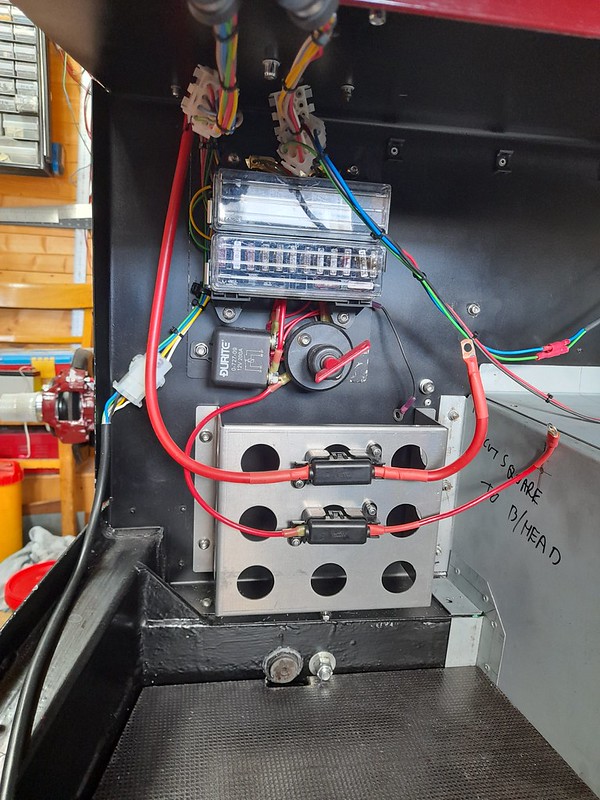

dashboard5 by Robin Martin, on Flickr

dashboard5 by Robin Martin, on Flickr dashboard4 by Robin Martin, on Flickr

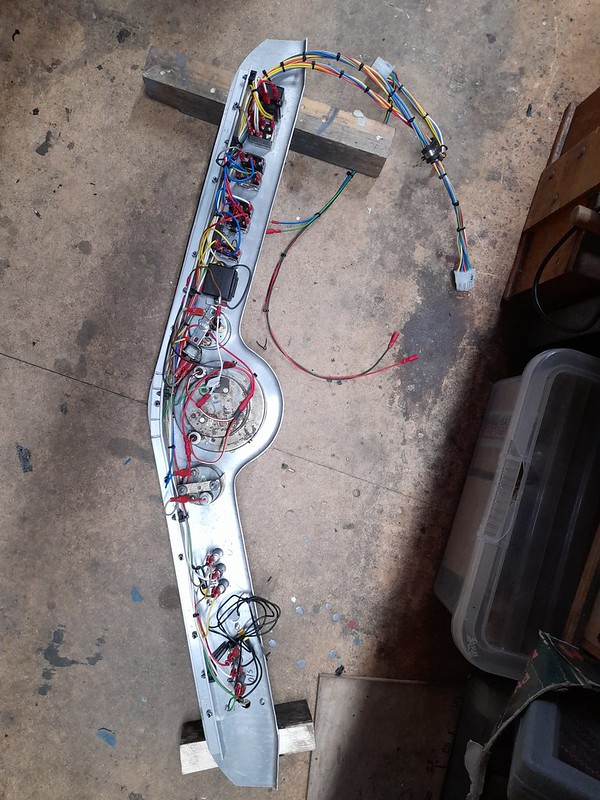

dashboard4 by Robin Martin, on Flickr loom2 by Robin Martin, on Flickr

loom2 by Robin Martin, on Flickr loom3 by Robin Martin, on Flickr

loom3 by Robin Martin, on Flickr

heater1 by Robin Martin, on Flickr

heater1 by Robin Martin, on Flickr heater2 by Robin Martin, on Flickr

heater2 by Robin Martin, on Flickr heater3 by Robin Martin, on Flickr

heater3 by Robin Martin, on Flickr

spare_wheel_1 by Robin Martin, on Flickr

spare_wheel_1 by Robin Martin, on Flickr spare_wheel_2 by Robin Martin, on Flickr

spare_wheel_2 by Robin Martin, on Flickr spare_wheel_3 by Robin Martin, on Flickr

spare_wheel_3 by Robin Martin, on Flickr radiator_new_old by Robin Martin, on Flickr

radiator_new_old by Robin Martin, on Flickr radiator_1 by Robin Martin, on Flickr

radiator_1 by Robin Martin, on Flickr radiator_2 by Robin Martin, on Flickr

radiator_2 by Robin Martin, on Flickr

bonnet_side_making by Robin Martin, on Flickr

bonnet_side_making by Robin Martin, on Flickr bonnet_side_1 by Robin Martin, on Flickr

bonnet_side_1 by Robin Martin, on Flickr bonnet_side_2 by Robin Martin, on Flickr

bonnet_side_2 by Robin Martin, on Flickr

bonnet_side_3 by Robin Martin, on Flickr

bonnet_side_3 by Robin Martin, on Flickr alternative_steering_wheel by Robin Martin, on Flickr

alternative_steering_wheel by Robin Martin, on Flickr exhaust_1 by Robin Martin, on Flickr

exhaust_1 by Robin Martin, on Flickr

Comment